Facing a few instruments with a dim backlight in the LCD display, I decided it was time to get rid of the aged CCFLs and replace them with white LEDS. I discovered a few of the instruments I needed to upgrade (Lecroy WaveRunner oscilloscope, Rohde & Schwarz CMU200, Agilent 8753ES) used the same Sharp LQ084V1DG21 LCD module. So I will describe here only how to modify the LCD to use LEDs, not how to install and power it in each particular instrument (I plan to write separate articles for that).

Be prepared to do some small and delicate work, even if it looks big and easy in photos.

Removing the CCFL tray

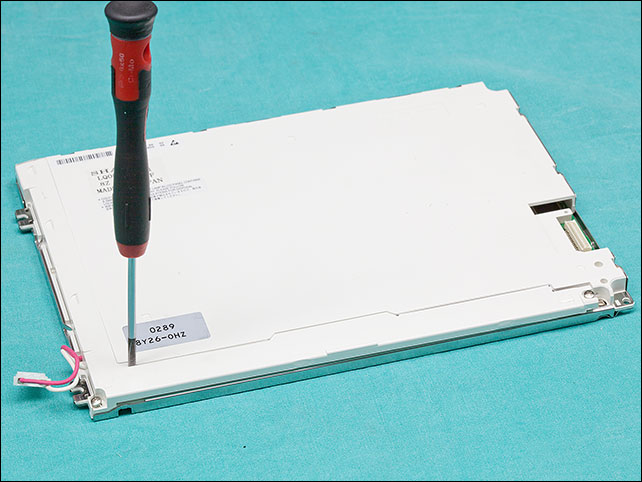

Place the LCD face-down on a clean surface and remove the two phillips screws at the bottom edge of the plastic “L” that serves as a removable tray for the CCFL tube. You can see those screws in the following picture. The third screw which is recessed at the right edge does not need to be removed.

The tray is removed by sliding it towards you, and it is not held in place just by the two screws. The end of the short side of the L clips in place and you will need to use a flat screwdriver or a plastic tool to force it down a bit. Start pulling down from the right screw of the long side of the L until you can place the screwdriver in the left corner. That plastic is very thin you don’t need to apply lots of force. Once that point is free, it slides down easily. All this is easier to understand by looking at the following picture. I left the loosened screws there just for the photo, you want to completely remove them.

Put the tray with the CCFL in a safe place, we will now prepare the LED strips.

CCFL Backlight issues

As you can see in the picture, you will find a thin CCFL tube and two sheets of thin reflective material. The backlight problems that we find in these instrumens are related to aging of the CCFL tube or degradation of the reflective sheets.

A clear sign of a weak and aged tube is blackened edges on the coating that should be white, on the inner side of the glass. The only solution for this is complete replacement of the tube, or substitution with LEDs.

Some reflective sheets have a mirror-like coating, others are just of the purest white you might have seen. If the problem in your LCD panel is that the reflective sheets have lost reflective properties (common in the mirror-type) or are twisted and have gotten in the way between the tube and the diffuser glass, you may just remove the sheets and keep the tube temporarily.

The long-term solution is to replace the tube with LEDs, and get rid of the unnecessary reflective sheets. Obviously you will need to replace the HV driver with a constant current source.

Preparing the LED strips

You want to get LED strips that are 4mm wide and rigid (actually a PCB strip), not flexible. If you can, get them in neutral color temperature and the highest LED density you can find. Most flexible strips are designed to work from 12VDC and include a resistor to limit current to the LEDs. The rigid strips for CCFL replacement usually do not include resistors, just many groups of three LEDs in series, and all in parallel. You don’t power these strips with 12V, you need a current controlled source. You will find info on the current source in other articles about LCD CCFL to LED conversion on this site.

You may be able to find many similar (or better) alternatives, but this is the kit I used. The link will eventually stop working but you can base your search on the title. You want a kit that includes two strips so you can solder wires to both strips. You should not worry about the length, any kit will be longer than what we need for this:

eBay: 490mm LED Backlight Strip Kit, Update Your 22″ 22 inch CCFL LCD Screen to LED

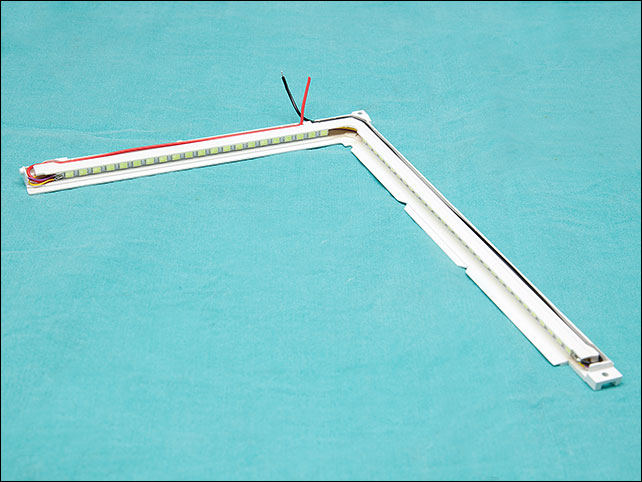

We need to cut two strips, for the short and long sides of the LCD. With the tray removed, you can see the openings on the side of the light diffuser glass, and those are the openings you need to cover with the LEDs. You can’t cut the strips exactly to length, you need to keep complete groups of series LEDs. In the strips I used, LEDS come in groups of three so I had to cut the strips to include complete groups of three LEDs, 21 for the short and 30 for the long side. And you have to avoid cutting the strip in the middle of a group. Don’t try to cover the full length of the glass opening at all costs, it is not necessary and later you may find the strips don’t fit in the tray. You also need to keep connections for power at the edges of the strips. This picture will help to understand.

The easiest way to power the strips is to connect and run a separate pair of wires for + and – for each strip. To keep things tidier, I decided to run just one wire for the positive and another for the negative, and route two wires internally to the strip on the opposite side, but it is an unnecessary complication you might want to save yourself from.

To hold the strips in place, you just slide them in the tray and put a few drops of superglue along its length, on the sides of the strip and against the walls of the tray. You want to keep them perpendicular to the walls of the tray. You might need to file the ends of the strip where the wires are soldered because the channel gets a bit narrower, just enough to not let the strip fit easily. You can see this if you click in this photo and look carefully:

This is how the finished tray will look like just before assembling it back to the panel.

After the conversion is done, you can use a lab supply to check that with 100mA at around 8.2V the backlight works. I am using here a 6632B that had a very dim VFD that I replaced with an OLED module.

If you need to get a connector for the LCD, look for something like this one. The link will eventually stop working but you can base your search on the title.:

eBay: JST 2.54 SM 2-Pin Connector plug Female & Male with Wires Cables

You probably want to avoid using a cheap switching regulator inside your instrument. It is easy to build a linear constant current supply, you can check it in my 8753ES LED conversion article.

If you have comments or feedback, let me know and you will help me improve this explanation.